European Ecodesign and Energy Labeling regulations

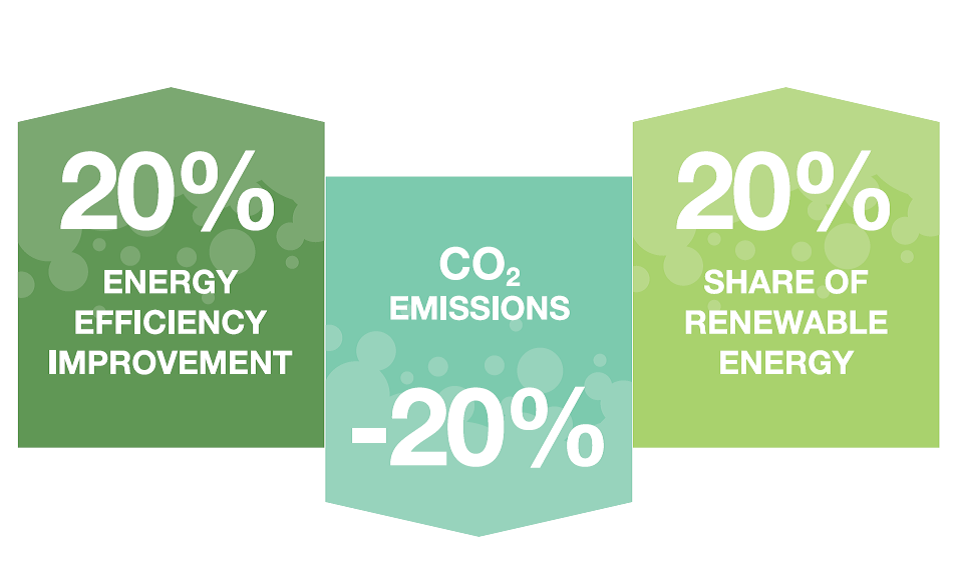

Carrier is committed to limiting the environmental impact of its products and solutions and reducing energy consumption. This commitment is in line with the targets of the European climate and energy package for 2020.

The energy efficiency improvement target strongly influences the heating, ventilation and air conditioning (HVAC) market. Indeed buildings are the largest consumers of energy today and, of that consumption, HVAC systems account for considerably more than other equipment. Providing its customers with energy efficient solutions is therefore now a key sustainable development opportunity for the HVAC industry.

In order to achieve these objectives, the European Union has developed two regulations on equipment consumption, including lighting, IT, water heating and HVAC (Heating, Ventilation, Air-Conditioning): Ecodesign (2009/125/EC) which establishes the framework for energy-using products and Energy Labelling (2010/30/EU) regulation for energy-related products sold in all 28 Member States.

Ecodesign regulation

Ecodesign is an approach to product design that encourages manufacturers to consider the environmental impact of the product over its entire lifecycle. In the European Union, the Ecodesign Directive establishes a framework for the setting of mandatory energy efficiency requirements for all energy-related products (ERPs), including heat pumps up to 400 kW. Because buildings have a thermal load depending on outdoor air temperature, the Seasonal Coefficient of Performance (SCOP) is a new European parameter to evaluate the energy efficiency of heat pumps. It replaces the Coefficient of Performance (COP), which measured the ratio of power consumed to power produced in the heating mode on a single operating point. Unlike its predecessor, the SCOP is representative of operation during the heating season as it includes seasonal variations by defining several realistic measurement points. Together, these contribute to classification in the correct energy efficiency class.

New Ecodesign European regulation for process chillers

The regulation EU/2015/1095 is setting Ecodesign requirements for professional refrigerated storage cabinets, blast cabinets, condensing units and process chillers. According to this new regulation, process chillers are appliances capable to provide cooling to a refrigerated appliance or system, the purpose of which is not to provide cooling of a space for the thermal comfort of people.

Seasonal energy performance ratio (SERP)

The SEPR is the ratio between the annual cooling demand and the annual energy consumption of the chiller. The SEPR is expressed in final energy kWh/kWh. The annual cooling demand and the annual energy consumption are calculated from 58 temperature bins corresponding to a reference average climate with ambient temperature ranging from -19° C to +38°C. The calculation is weighted by the number of hours occurring at each temperature bin. (Climate data). The thermal load varies from 80 to 100% for each temperature bin between 5 and 35°C. Below 5° the EER remains constant as well as above 35°C. The SEPR takes into account relativity low load variations, therefore it is significantly driven by the energy efficiency at full load.

A few more information

- The standard rating condition for the evaporator is inlet -2°C and outlet -8°C. However, the inlet temperature can be lower if the chiller cannot operate at 6 K delta T.

- Process chillers are intended to operate all year round so the SEPR calculation doesn’t take into account the power input in Stand-By or OFF modes.

- SEPR is always calculated at a fixed evaporator outlet temperature.

- Technical standard EN14825 is under revision to include SEPR calculation.

- “Transitional measurement & calculation methods” are available until the publication of a revised standard in 2017.

Process chillers are split into two sub-categories:

- “Low temperature” process chillers capable to operate at an evaporator outlet temperature of -25°C.

- “Medium temperature” process chillers capable to operate at an evaporator outlet temperature of -8°C

From 1 July 2016 (Tier 1) and 1 July 2018 (Tier 2) the Seasonal Energy Performance Ratio (SEPR) for new chillers placed on the market shall not fall below the following values.

The efficiency requirements are lowered by 10% for process chillers operating with a refrigerant with a Global Warming Potential (GWP) below 150, eg: pure R-1234ze, ammonia, hydro-carbons. All Carrier chillers with brine N° 6 or 6B are subject to Ecodesign regulation N° 2015/1095. The units below are compliant with the efficiency requirements applicable from July 1st 2016 as following: 30RBS039-160 Opt 6B / 30RBSY039-160 Opt 6B / 30RB162-402 Opt 6B / 30RBM / 30RBP / 30WG 020-090 Opt 6B / 30RW 110-300 Opt 6 / 30XW 1154 Opt 6 / 30XWP 512, 562 &1012 Opt 6. From 2018, another regulation is expected to set Ecodesign requirements for “High temperature” process chillers operating at an evaporator outlet temperature of +7°C.

Energy labelling regulation

The aim of the Energy Labelling regulation is to provide end users with easy to understand information on product energy efficiency. In addition, the European Energy Labelling regulation classifies products from G to A, according to their efficiency. This pulls the market towards more energy-efficient products by improving consumer information. Starting September 26, 2015, heat pumps up to 70 kW, as commercial heat pump products, are covered by the Ecodesign and Energy Labelling regulations. Conformity is mandatory for a product to obtain the CE marking. Carrier heat pumps are all in the classes A to A ++ due to their advanced energy efficiency design.

For more information, visit: www.ecodesign.hvac.carrier.com